Blowouts are one of the most serious risks in oil and gas drilling. A blowout occurs when formation pressure becomes higher than the pressure inside the wellbore, allowing oil, gas, or drilling fluids to flow uncontrollably to the surface. Most blowouts develop due to pressure imbalance, missed indicators, or failures in well control systems.

Investigations after major incidents, including the Deepwater Horizon event in the Gulf of Mexico, show that blowouts often escalate over time. Early warning signs are usually present, but crews may miss or misinterpret them due to operational pressure, equipment limits, or incomplete data. Understanding what causes a blowout helps drilling teams reduce risk, protect personnel, and meet regulatory requirements.

Key Takeaways

- Pressure imbalance is the leading cause of drilling blowouts

- Well kicks are early indicators of lost well control

- Accurate mud weight supports pressure stability

- BOP stacks act as the final physical safety barrier

- Monitoring and training reduce escalation risk

What Is a Blowout in Well Drilling?

A blowout is the uncontrolled release of formation fluids when wellbore pressure drops below formation pressure. Once this balance is lost, fluids can migrate rapidly toward the surface and create fire, explosion, and environmental hazards.

Under normal conditions, weighted drilling mud provides hydrostatic pressure to contain formation fluids. Crews monitor this balance using flow sensors, pit volume measurements, and pressure gauges. When monitoring fails or response is delayed, blowout risk increases.

Common Causes of Blowout Incidents

Blowouts rarely happen because of a single issue. They usually result from a combination of factors. Understanding the common causes helps us manage risk and prevent incidents.

Equipment Failures

Worn seals, faulty valves, or hydraulic problems can weaken the barriers that control well pressure. When equipment doesn’t function properly, it becomes easier for pressure to escape, increasing the chance of a blowout. Regular maintenance and inspections are critical to catch these issues early.

Human Error

Mistakes in judgment or delayed responses can contribute to loss of well control. Misreading pressure data or not following proper procedures can escalate small issues into serious incidents. Proper training, clear communication, and strict safety protocols are essential to reduce this risk.

Geological Uncertainty

Unexpected rock formations or high-pressure zones can create conditions that are difficult to predict. Even well-designed wells can encounter pressures or formations that challenge equipment and crew. Careful geological analysis and real-time monitoring help manage these uncertainties.

Severe Weather

Extreme weather events, such as storms or hurricanes, can disrupt operations and affect equipment performance. High winds, heavy rain, or flooding may interfere with control systems and make rapid response more difficult. Planning for weather contingencies is an important part of safe operations.

Pressure Imbalance and Well Kicks

Maintaining stable pressure is the foundation of well control. Drilling fluid pressure must remain higher than formation pressure without exceeding the fracture strength of the surrounding rock. Small pressure changes can quickly affect well stability if crews do not detect them early. Continuous monitoring helps teams identify pressure shifts and respond before control is lost.

Pressure conditions can change due to:

- Formation depth and permeability

- Changes in drilling rate

- Circulation losses

- Pipe movement during tripping

Even small deviations can destabilize the well if crews do not detect them early. Early detection allows crews to correct pressure before formation fluids enter the wellbore. Timely response reduces the risk of well kicks and uncontrolled flow. Consistent monitoring supports safe and stable drilling operations.

What Is a Well Kick?

A well kick occurs when formation fluids enter the wellbore due to insufficient hydrostatic pressure. Kicks are the earliest warning sign of declining well control. If not controlled quickly, a kick can grow in size and increase wellbore pressure. Early recognition allows crews to shut in the well and restore pressure safely.

Common causes include:

- Low drilling mud density

- Unexpected pressure zones

- Inadequate flow monitoring

- Improper circulation practices

Early detection allows crews to shut in the well and restore pressure before escalation. This action helps stop further fluid entry into the wellbore. Quick response reduces the chance of a blowout.

How Well Kicks Escalate Into Blowouts

When formation fluids enter the wellbore, they move toward lower-pressure zones. Gas kicks are especially dangerous because gas expands as it rises, increasing internal pressure and accelerating flow.

Without prompt response, escalation may include:

- Rapid gas expansion

- Loss of hydrostatic balance

- Increased stress on casing and surface equipment

- Failure of primary pressure barriers

Immediate shut-in procedures and controlled circulation are critical to regaining control. These steps help stabilize wellbore pressure and limit further influx. They allow crews to remove formation fluids in a controlled manner.

Why Mud Weight and Pressure Control Matter

Correct mud weight selection is central to blowout prevention. Mud that is too light allows formation fluids to enter the wellbore. Mud that is too heavy can fracture formations and cause lost circulation.

If the mud weight is too low:

- Kick frequency increases

- Pressure control weakens

If the mud weight is too high:

- Formation fracture may occur

- Lost circulation can develop

- Cement integrity may be compromised

Routine mud testing and real-time pressure monitoring help maintain stable drilling conditions. These practices help crews detect pressure changes early. Early action reduces the risk of well kicks and loss of control.

Advanced Pressure Management Practices

Modern drilling operations use structured pressure management systems to reduce risk. Managed Pressure Drilling allows precise control of bottom-hole pressure using automated equipment and real-time data.

Common practices include:

- Pressure modeling

- Formation Integrity and Leak-Off Tests

- Kick tolerance calculations

- Mud weight adjustments

These methods reduce uncertainty and improve well stability in complex formations. They allow crews to respond quickly to pressure changes. Consistent application helps prevent uncontrolled fluid flow.

Preventing Blowouts During Well Drilling

Effective blowout prevention combines engineering controls, disciplined procedures, and workforce competency. It relies on proper planning, continuous monitoring, and fast response to changing well conditions. Well-trained crews ensure that safety systems, including blowout preventers (BOPs), are used correctly during critical events.

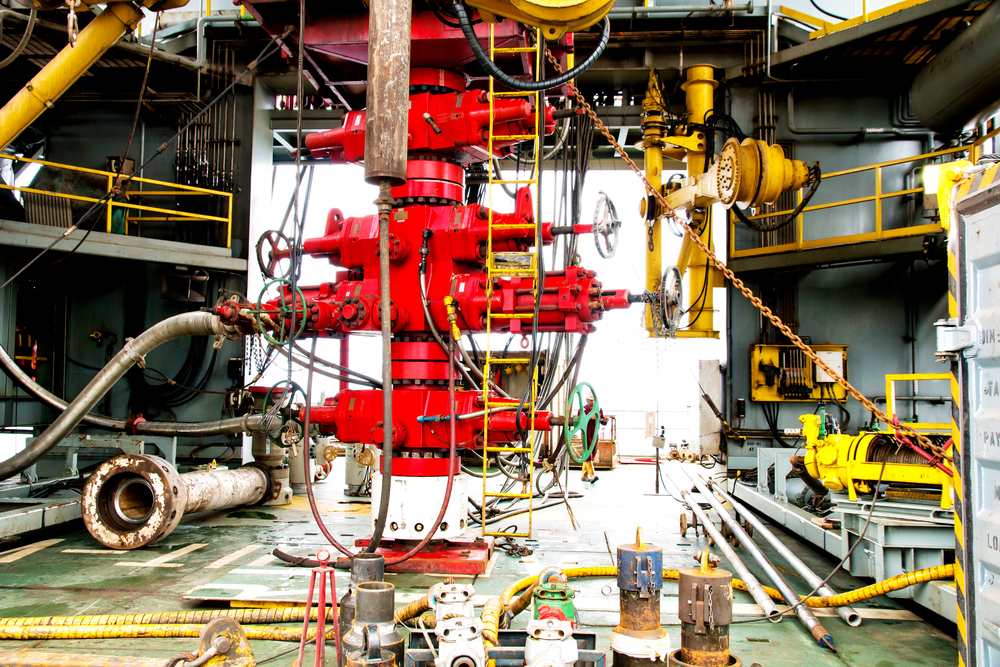

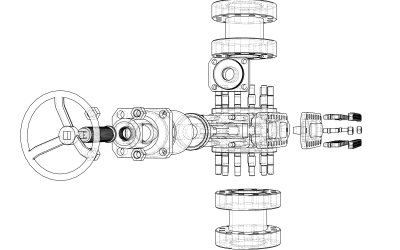

Blowout preventers are a primary line of defense against uncontrolled well pressure. Installed on the wellhead, BOP systems are designed to seal, control, and monitor the wellbore during drilling operations. Annular and ram-type BOPs work together to shut in the well, contain formation fluids, and maintain well control when abnormal pressures are detected.

Best practices include:

- Pre-drill pressure modeling to anticipate formation behavior

- Real-time monitoring systems to detect pressure changes early

- Clear shut-in procedures using properly maintained BOP equipment

- Routine crew training on BOP operation and emergency response

Integrated well control programs reduce reaction time and limit escalation during critical events. When combined with reliable BOP systems that are regularly tested and maintained, these programs give crews clear steps to follow during emergencies. Consistent application helps prevent small pressure events from developing into full-scale blowouts.

Why Blowout Prevention Matters

Reliable well control equipment supports safety, efficiency, and regulatory compliance throughout drilling operations. From pressure monitoring systems to BOP stacks, the right equipment protects personnel and reduces the risk of uncontrolled releases.

As a supplier of blowout preventer systems, we provide dependable well control solutions designed to meet industry safety and performance standards. Our equipment supports drilling operations across demanding environments, including deepwater projects.

Looking for dependable blowout preventer systems? Contact us to access proven well control solutions, technical expertise, and equipment engineered for high-pressure drilling conditions.