The oil and gas industry is an essential part of our world. Unfortunately, it can also be a dangerous field of work. Even with safety measures in place, oilfield accidents can occur and be very dangerous to everyone involved.

How safe is your oil drilling operation? These 3 important factors could be contributing to an increased risk of accidents. Share on XThe Root Causes

The first step to preventing oilfield accidents is understanding what typically causes them. While any number of factors may cause an immediate problem, several underlying causes tend to be ultimately responsible. These underlying causes include:

- Fires

- Equipment failure

- Inadequate training

1) Fires

Combustible gases or liquids under high pressure can cause the tops of their containers to blow off, even with pressure safety mechanisms. These explosions are bad enough on their own and can cause serious injury to anyone nearby. However, sparks from nearby welding jobs can set the escaping gas on fire. Since oil fields produce a constant supply of highly flammable liquid, flames spread rapidly and require a lot of care to extinguish.

The best way to combat this issue is to be proactive. Keep an eye on all high-pressure vessels or substances and make sure they never reach dangerous levels. Most importantly, control any potential sources of fire or sparks even closer than you already do. Even a single solitary spark could cause serious injuries and widespread disaster.

2) Equipment Failure

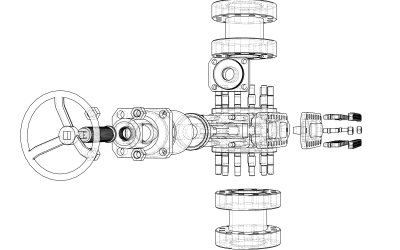

Corroded pipes, manufacturer flaws, or equipment malfunctions can cause oilfield equipment to leak or fail unexpectedly. Of course, equipment failure can lead in turn to pressure blowouts or trouble controlling the flow of oil and gas. Keep either scenario from happening by taking care to keep your equipment clean, tested, and outfitted with the newest and most durable parts.

Pro Tip: Keep your oilfield outfitted with the best Ram BOPs to prevent leaks and ensure a long life for your equipment!

3) Inadequate Training

Finally, how much training have your employees received? Do they know how to properly handle all the equipment and what to do in an emergency situation? Test their knowledge and make sure they’re ready for the unexpected.

Staying Safe on the Job

While working on the oilfield presents a fair number of risks, many potentially dangerous situations can be avoided with a little forethought. Make sure to provide plenty of training to your employees, keep your equipment tested and up to date, and keep an eye on any potentially dangerous work or scenarios. Care and caution will make your oilfield a much safer place to work.

Connect with us to learn more about oilfield safety and lowering potential risks.